This fork and tree set I have are new and have never been apart. I’ve had them in a box for over 25 years. Perhaps you have a Meihatsu that needs a new front end. If you want them, it's 150 bucks. 952-607-6063

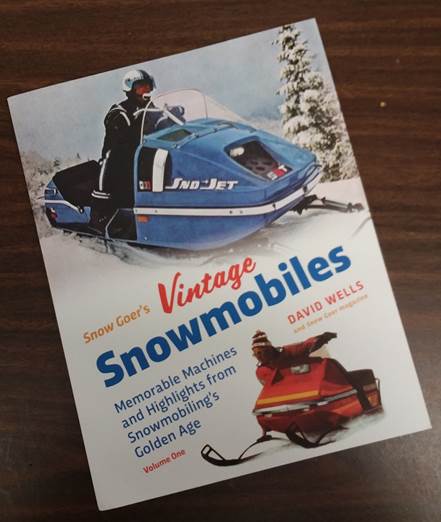

My Buddie Dave Wells in Rochester NY has just released a new vintage snowmobile book. Dave is a snowmobile specialist and writes for SnowGoer magazine.

My Buddie Dave Wells in Rochester NY has just released a new vintage snowmobile book. Dave is a snowmobile specialist and writes for SnowGoer magazine.

This book covers interesting sleds from 1968 to 1986. 28 collectable sleds are covered, each on two pages and he mentions the 70s stock racing war in his 126 page hardbound book. Over 100 color photos.

This is Colten Korolewich from Beauséjour, Manitoba. He drives anything with wheels, tracks and a hull bottom. He is a pretty spectacular at doing those nasty high stunt jumps while hanging in the air as he twists his bike around and upside down in miraculous ways. He can be found at super nasty mud races on an ATV with ultra-aggressive tires that does fling mud.

This is Colten Korolewich from Beauséjour, Manitoba. He drives anything with wheels, tracks and a hull bottom. He is a pretty spectacular at doing those nasty high stunt jumps while hanging in the air as he twists his bike around and upside down in miraculous ways. He can be found at super nasty mud races on an ATV with ultra-aggressive tires that does fling mud.